High Pressure Die Casting

A SINGLE SOURCE FOR DIE CASTING THROUGH MACHINING & ASSEMBLY

As the saying goes that "Casting is the foundation of industry". VERNAL's engineering team possess complete and very capable casting experience that from the basic Sand Casting and expanding to investment Casting, Gravity Casting, and High Pressure Die Casting.

Therefore, VERNAL's engineering team provides mature casting technology and to satisfy our customers' requirements on casting quality with its complex design.

Therefore, VERNAL's engineering team provides mature casting technology and to satisfy our customers' requirements on casting quality with its complex design.

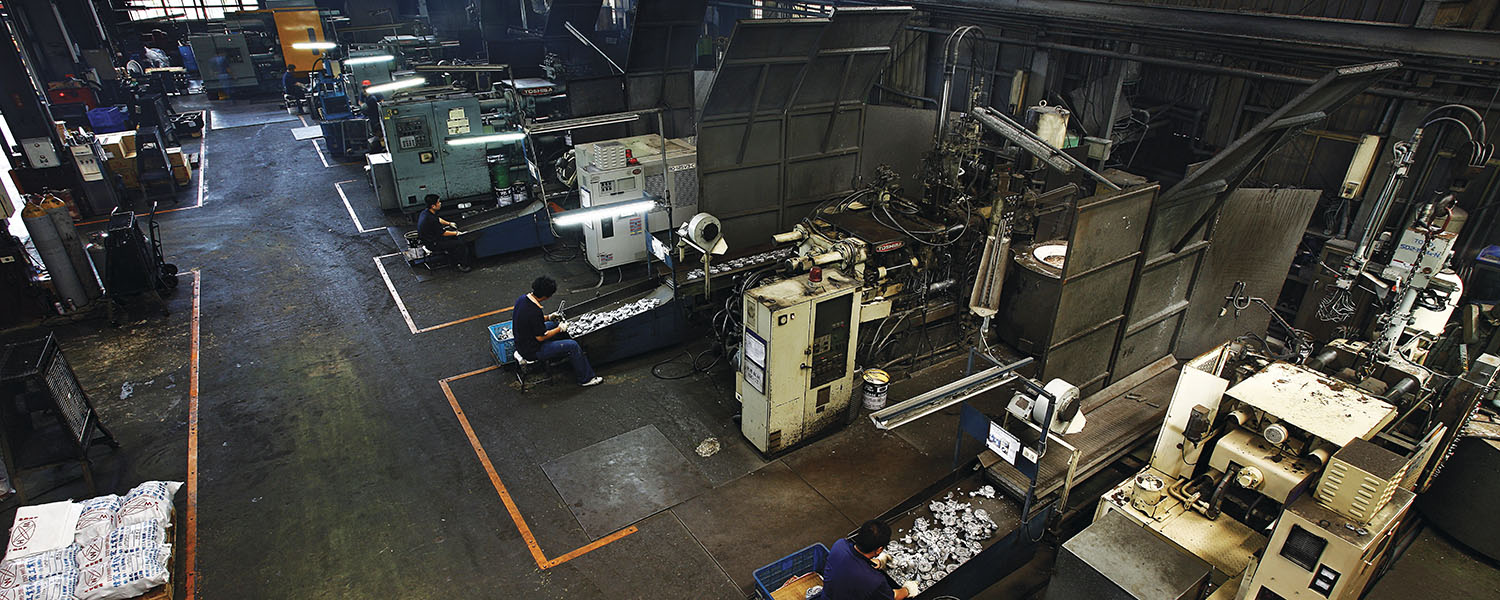

HIGH PRESSURE DIE CASTING

Single Source For Die Casting Through Machining & Assembly, Pressure Die Casting, Machining, Finishing, Assembly & Testing It is basic requirements to select a die casting supplier-with professional tooling design and building, superior die casting technique capabilities.

VERNAL excels in putting superior technology together with engineering specialists to design and fabricate special machine for secondary operations additionally.

We help our customer to increase profitability with combination of several labors force with intensive operations consistantly and then outcome with a single automated process.

Capabilities include

Die Casting

- Die casting machines are ranged in size from 30 to 800 ton capacity.

Secondary Operations

- Automated and manual skilled machining operations include drilling, Tapping, and reaming.

- Mechanical finish includes tumbling, vibratory finishing, burnishing, Shot blasting, and buffing.

Product Finishing

- Include electroplating, dichromating, painting, powder coating, and anodizing.

- Fully automated and semi-automated equipment design and building for precise demand assembly.

- Skilled & technical manual assembly for complex product.